Thailand, Bangladesh 250 tons of rice bran extraction production line expanded http://www.ricebranoilplant.com

2016年9月27日星期二

China best rice bran oil machine

China best rice bran oil machine

http://www.ricebranoilplant.com

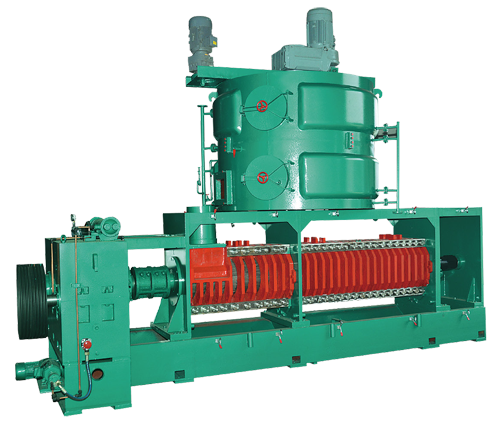

Rice Bran Oil Press Machine Features:

1. Main material is stainless steel.

2. Oil press machine has simple design, elegant appearance.

3. Stable functions, simple maintenance, and safe operation.

4. One time squeezing with three times pressing, high productivity.

Rice Bran Oil Press Machine Main Advantages:

1. Electricity saving: the electric power can be reduced by 40% in the same output. In details, the machine can save 6 kws/h a day that is worth about 30 RMB.

2. Labor Saving: 60% labor force can be saved for equal output. Ony one or two persons are needed for the production, which can save about 40 RMB/day.

3. Wide application: more than 20 kinds of oil crops can be pressed by this machine, such as, peanuts, sesame, vegetable seeds, soybean, sunflower, cottonseeds, flax, etc.

4. Oil Purity control: the vaccum oil filter is used to remove the residues in order to ensure the oil quality which can meet the health and sanitary regulation.

5. Less ocuppied area: only needs 10 ~ 20m2 for production.

6. The oil left in cakes is less than 6%. The cake thickness can be adjusted when the machine out of work, and the cakes also can be used for animal feed.

http://www.ricebranoilplant.com

Rice Bran Oil Press Machine Features:

1. Main material is stainless steel.

2. Oil press machine has simple design, elegant appearance.

3. Stable functions, simple maintenance, and safe operation.

4. One time squeezing with three times pressing, high productivity.

Rice Bran Oil Press Machine Main Advantages:

1. Electricity saving: the electric power can be reduced by 40% in the same output. In details, the machine can save 6 kws/h a day that is worth about 30 RMB.

2. Labor Saving: 60% labor force can be saved for equal output. Ony one or two persons are needed for the production, which can save about 40 RMB/day.

3. Wide application: more than 20 kinds of oil crops can be pressed by this machine, such as, peanuts, sesame, vegetable seeds, soybean, sunflower, cottonseeds, flax, etc.

4. Oil Purity control: the vaccum oil filter is used to remove the residues in order to ensure the oil quality which can meet the health and sanitary regulation.

5. Less ocuppied area: only needs 10 ~ 20m2 for production.

6. The oil left in cakes is less than 6%. The cake thickness can be adjusted when the machine out of work, and the cakes also can be used for animal feed.

Palmex Indonesia 2016!!! Santika Premiere Dyandra Hotel&Convention Medan.

Palmex Indonesia 2016!!! Santika Premiere Dyandra Hotel&Convention Medan.

Time: 4-6,October;

Add: 119

Email: firstecd07@oilfa.com

Web: http://www.palmprocess.com

Time: 4-6,October;

Add: 119

Email: firstecd07@oilfa.com

Web: http://www.palmprocess.com

Small edible oil amchine

Small edible oil amchine www.ricebranoilplant.com

1. Introduction of oil press machine line

(1) Function: Leaching system is an oil extraction through soaking or spraying pre-pressed cake by a certain organic solvent. The principle of this part is the different solubility of solvent.

(2) Use range: Solvent extraction fits for pre-press extraction of high-oil-content materials and direct once time extraction of low-oil-content materials.

(3) Main parts: The extraction series includes rotary extractor, toaster, 1st evaporator, 2nd evaporator, stripping tower, condenser, etc.

2. Main parts of oil press machine line

(1) Solvent pumps: continuously spray solvent to the rotary-type extractor

(2).Roary extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil).

(3). DTDC: usd to separate the solvent from the wet meal.

(4). Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline wter, at last the reactant precipitate, reaching the goal of purifying.

(5). Miscella tank 2nd: the purified miscella will be pumped into it.

(6). Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

(7). condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

1. Introduction of oil press machine line

(1) Function: Leaching system is an oil extraction through soaking or spraying pre-pressed cake by a certain organic solvent. The principle of this part is the different solubility of solvent.

(2) Use range: Solvent extraction fits for pre-press extraction of high-oil-content materials and direct once time extraction of low-oil-content materials.

(3) Main parts: The extraction series includes rotary extractor, toaster, 1st evaporator, 2nd evaporator, stripping tower, condenser, etc.

2. Main parts of oil press machine line

(1) Solvent pumps: continuously spray solvent to the rotary-type extractor

(2).Roary extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil).

(3). DTDC: usd to separate the solvent from the wet meal.

(4). Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline wter, at last the reactant precipitate, reaching the goal of purifying.

(5). Miscella tank 2nd: the purified miscella will be pumped into it.

(6). Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

(7). condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

2016年9月13日星期二

2016年9月12日星期一

50TPD Palm Oil Refining And Fractionation Project In Cameroo

50TPD Palm Oil Refining And Fractionation Project In Cameroo

Raw material: crude palm oil

Capacity: 50 Ton per day

http://www.palmprocess.com

Raw material: crude palm oil

Capacity: 50 Ton per day

http://www.palmprocess.com

2016年9月6日星期二

4 Advantages of Soybean oil Machines

soybean→Magnetic separation→Cleaning→crusher→flaker

→ Extrusion Puffing →Counter→current drying→To leaching plant

1.Full continuous and mechanized operation, and with electrical interlocking control system.

2.The equipment layout is in tower structure, and the material flow by relying on gravity to reduce power consumption.

3.Take into consideration the environmental requirements in modern industry. The workshop is also equipped with the dedusting system with high performance, so as to meet the requirements of production and environmental protection.

4.When producing germ meal, the roller softening pot can better meet the flaking technical requirements.

5.Select scraper conveyor as much as possible, which can effectively reduce raw material crushing, improve solvent permeation into the material layer and increase the extraction efficiency.

Safety:

1) We use auto welding machine to make the reactor,which can quarrantee the quality of welding seam,avoid cracking and has a long life for about 8 years.

2) Professional heating treatment and x-ray detection chamber for welding seam .3) Vacuum system to prevent oil gas be back to reactor causing accident.

4) With professional thermometer , professiona pressure gauge and safety valve.

2) The exhaust gas will be recycled for heating reactor ,no gas pollution

3) Well sealing on every junction parts to prevent gas leak,no smelly

2) The exhaust gas will be recycled for reactor heating.

Environment friendly:

1) Dedusting system to prevent gas and dust from coal burning

Longer service life :Using Q345R special steel plate ,welding seam with auto welding an will get heating treatment and x-ray detection to extend the life of reactor to the most extend, and the life will 8 years.

Energy saving:

1) Well sealing for heating system ,no gas leak and saving fuel.

More info visit:http://www.soybeanpress.com

3 Steps to Get High Quality Rapeseed Oil

Rapeseed oil machine process flow:

1. Pretreatment workshop flow for rapeseed oil proceessing equipment

rapeseed→ magnetic box → cleaning →husking machine → flaking → oil press → oil filter→ to extraction workshop 2. Extraction workshop flow for rapeseed oil processing equipment

extractor → mixed oil → 1st and 2nd evaporation → stripping tower → crude rapeseed oil

Wet meal → DTDC toaster → cake

3. Refinery workshop flow for rapeseed oil processing equipment rapeseed oil → degumming and deacidification→ decolorization →deodorization → refined rapeseed oil.

rapeseeds oil machine types:

More info visit:www.rapeseedmill.com

订阅:

评论 (Atom)